Process Parts and Spare Parts List

Standard parts or drawing components for various process equipment and production facilities

We custom-made and supply. In particular, nickel-pipes can be processed up to 1mm.

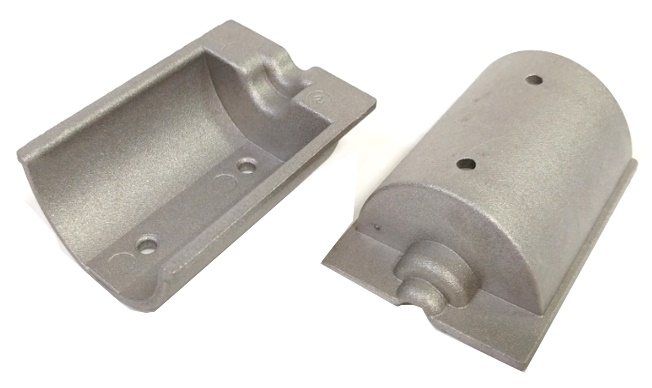

| Commodity | Al Board | Heat Baking Case | Clamp Fastener | O-Ring |

| Figure |  |

|

|

|

|

Spec |

Al Sanding |

Ceramic Cap |

SUS304, Kinds of Diameter |

Viton/ P8/P10/P20/P30 etc |

|

Application |

Heating Protecting Cap |

Heating Socket Cap |

Joints for Parts or Tubes |

Prevent Leakage of Oil,Gas,Water |

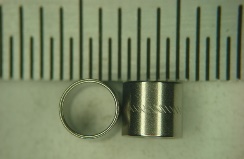

| Commodity | Ni Pipe, SUS Pipe | SUS Copper Clad Pipe | Ni, Kovar Pipe |

| Figure |  |

|

|

|

Spec |

Ø0.2/ Ø0.5 / Ø1.0 /Ø1.5/Ø2.0 /Ø3.0etc |

Ø1.0 /Ø1.5/Ø2.0 /Ø3.0~etc |

Ø1.0 /Ø1.5/Ø2.0 /Ø3.0~etc |

|

Application |

Vacuum, precision parts, medical parts,Super-high-precision tube parts. etc |

||

|

Remarks |

日本中島 |

日本中島 |

日本中島 |

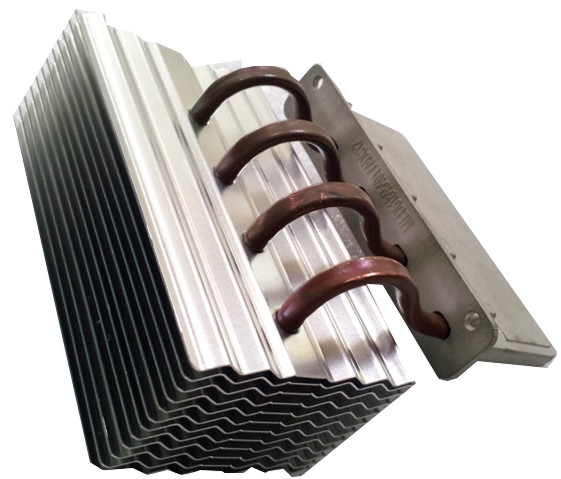

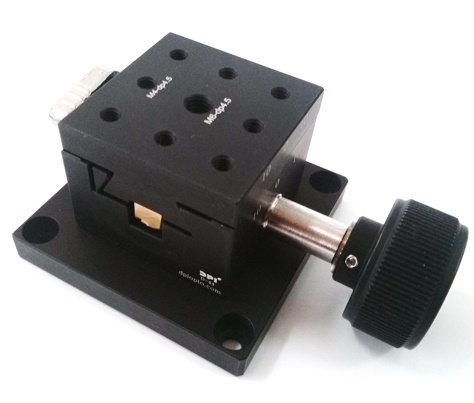

| Commodity | Al Heat Sink Pipe | Induction Heat Coil | Dovetail Stage | F-Mount Pallet Jig | |

| Figure |  |

|

|

|

|

|

Spec |

Cu Heat Pipe, Al Radiator Fin |

Copper Pipe, OFC Plate |

Manual XYZ Dovetail |

SUS manufacturing |

|

|

Application |

Air-Conditioner, High Efficacy parts |

Induction Heating Plate |

Various Mechanical Processes |

Vacuum Mounting |

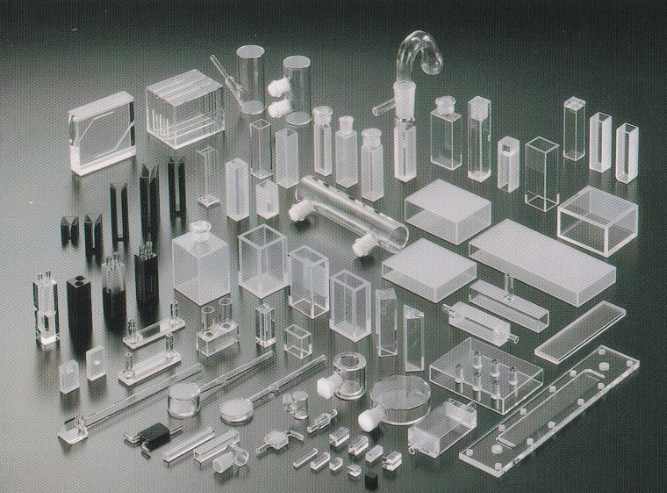

Various drawings of SUS, Ceramic, Quartz and Carbon materials required for production process,

development process, and mass production industrial fields.

We develop, manufacture, and supply processing parts.

|

|

|

|---|

| Characteristics of Materials | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Ceramic

|

Alumina (Al2O3) |

Mullite (3Al2O3 2SiO2 ) |

Cordirite

|

Silicon Carbide (SiC) |

Silicon Nitride (Si3N4) |

Aluminum Nitride (AIN) |

Zirconia (ZrO3) |

Boron Nitride (BN) |

||||||||||

|

Materials Code |

CA100 |

CA99 |

CA96 |

CA92 |

CMW |

CMB |

CCL |

CSC10 |

CSN10 |

CSN20 |

CAN100 |

CZ |

CMZ |

CB10 |

CB20 |

CB30 |

||

|

Appearance |

Dense |

Porous |

Dense |

Porous |

Dense |

Dense |

Dense |

Dense |

Dense |

|||||||||

|

Density(g/cm3) |

3.95 |

3.93 |

3.72 |

3.65 |

2.0 |

3.2 |

1.5 |

3.2 |

3.2 |

3.2 |

3.4 |

6.0 |

5.6 |

2.1 |

1.9 |

1.7 |

||

|

Water Absorption(%) |

0 |

0 |

0 |

0 |

10~20 |

0 |

15~25 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

||

|

V.Hardness(HV1.0, GPa) |

22 |

16 |

14 |

12 |

- |

10.8 |

- |

21.6 |

13.6 |

13.8 |

10.8 |

12.3 |

9.8 |

- |

- |

- |

||

|

Toughness(MPam1/2) |

3.0 |

3.0 |

2.7 |

2.5 |

- |

- |

- |

4.9 |

4.8 |

6.0 |

- |

4.5 |

6.5 |

- |

- |

- |

||

|

Coefficient of Thermal Expansion(x10-6/℃) |

Parallel 5.3 |

7.2 |

7.2 |

7.1 |

4.1 |

5.0 |

0.5 |

4.0 |

2.6 |

2.6 |

4.8 |

10.5 |

10 |

4.6 |

- |

- |

||

|

Vertical 4.5 |

||||||||||||||||||

|

Thermal Conductivity(w/m.k) |

42 |

32 |

24 |

16 |

1 |

5 |

1 |

60 |

20 |

30 |

150 |

3 |

3 |

49 |

- |

|||

|

Thermal Shock Resistnce(∆T) |

250 |

200 |

200 |

200 |

- |

- |

00 |

400 |

750 |

750 |

350 |

300 |

450 |

900 |

1000 |

1000 |

||

|

Max Temp(℃) |

1500 |

1500 |

1500 |

1400 |

|

|

|

1750 |

1100 |

1200 |

1500 |

1500 |

1000 |

1100 |

1100 |

1100 |

||

|

Dielectric Strength(106 v/m) |

47 |

12 |

12 |

12 |

- |

12 |

- |

- |

10 |

- |

14 |

- |

- |

- |

- |

- |

||

|

Dielectric Constant(1MHz) |

Parallel 11.5 |

9.9 |

9.4 |

8.9 |

- |

7.4 |

- |

- |

- |

- |

8.6 |

- |

- |

- |

- |

- |

||

|

Vertical 9.3 |

||||||||||||||||||

|

Characteristics of Materials |

|

||||||||

|---|---|---|---|---|---|---|---|---|---|

|

Carbon

|

IMF307 |

GS203R |

IGS604 |

SED40 |

GE103 |

||||

|

Bulk Density(g/cm3) |

1.99 |

1.81 |

1.86 |

1.82 |

1.76 |

||||

|

Bending Strength(Kg/cm3) |

920 |

520 |

550 |

550 |

320 |

||||

|

Electrical Resistivity(uΩCm) |

1300 |

1150 |

1100 |

1300 |

750 |

||||

|

Shore Hardness |

77 |

53 |

53 |

54 |

36 |

|

|||

|

Coefficient of Thermal Expansiom(x10-6/℃)) |

7.3 |

4.9 |

4.6 |

- |

3.2 |

||||

|

Thermal Conductivity(Kcal/m.hr℃) |

90 |

100 |

110 |

- |

130 |

||||

|

Ash(%) |

0.05 |

0.05 |

0.05 |

- |

0.1 |

||||

|

Max Grain Size(mm) |

- |

0.02 |

0.02 |

- |

0.8 |

||||

|

Method Mfg. |

CIP |

Mould |

CIP |

CIP |

Extrude |

||||